Storage and Maintenance of Struts & Straps

In order to complete a successful rescue, all equipment must be in working order. Along with struts, ratchet straps play an important role in vehicle stabilization and that’s why they are included in every Res-Q-Jack kit purchase. Below are a few tips on making sure your struts and straps are in good working condition. The time to find out they are in need of replacement isn’t on scene.

In order to complete a successful rescue, all equipment must be in working order. Along with struts, ratchet straps play an important role in vehicle stabilization and that’s why they are included in every Res-Q-Jack kit purchase. Below are a few tips on making sure your struts and straps are in good working condition. The time to find out they are in need of replacement isn’t on scene.

Strut Storage

- Store jack in fully collapsed position.

- Keep jack in a dry environment. Exposure to too much moisture may result in rust and/or decreased effectiveness of straps.

- Beware of strap storage environment. Nylon and polyester have adverse affects when in prolonged exposure to ultraviolet light, when exposed to sunlight or arc welding, and when temperatures are above 200° F.

Strut Maintenance

- Periodically oil crank handle lightly at each side of the jack body. Remove jack cap and grease internal gearing as needed (Chevron Black Pearl grease or equivalent is recommended).

- A light lubricant should be applied with a rag to outside of inner tube, being careful not to excessively lubricate. Remove any excess grease or oil. To keep the extensions sliding smoothly, this process is beneficial for all extension tubings and the inner tubing of all X-Strut series struts.

- Inspect and clean all components of strut following each use. Visually inspect welds, hardware, retaining pins, straps, chains, hooks, and other parts. Look for cracks, dents, and other small imperfections. Replace torn, frayed, worn, broken, bent, or missing parts before use. See below for some examples of strap damage.

- Contact Res-Q-Jack at 1-800-466-9626 for refurbishing or component replacement requests, or if you have any questions about the safety of your strut.

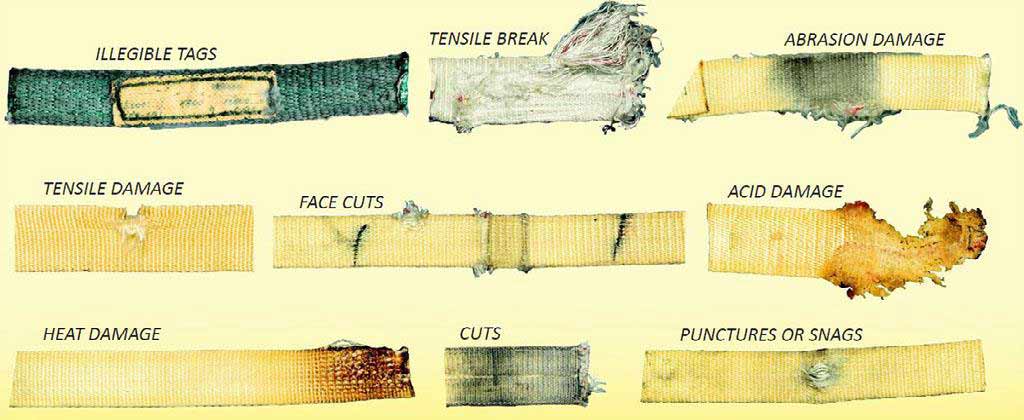

Examples of Strap Damage

Shown in extreme conditions below, straps should be removed from service and replaced if any signs of damage are visible. Look for any of the following:

- Cuts, holes, surface abrasion, crushed areas, or any separation of load-carry stitch pattern

- Burns or chemical damage

- Hardware, fittings, or tensioning devices which are broken, bent, twisted, cracked, or have nicks and gouges

- Knotted webbing or damaged loop ends

- Splices or other makeshift repairs